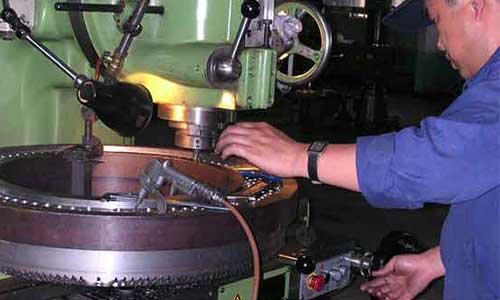

Analysis of the causes of tool damage and countermeasures

Metal objects strayed into the cutting room

The casting head is heated by a heat medium, and the external insulation cotton and iron sheet are used for protection.

With the aging of the insulation cotton, the fastening screw on the iron sheet falls off and enters the cutting room, causing serious damage to the cutting knife.

In addition, during the maintenance process of the pelletizer, the phenomenon that the bolts on the fixed knife seat are not fastened in place and loosen and fall off cause the damage of the cutting knife.

Therefore, the operator should strengthen the maintenance of the surrounding environment of the pelletizer to avoid hard damage to the cutting knife caused by foreign objects entering the cutting chamber.

Maintenance personnel should be careful during the maintenance process, and apply bolt bite (anti-loosening agent) to the bolts that are disassembled and reassembled to ensure safety.

Effect of titanium in slices

Titanium dioxide (TiO₂) is used as a matting agent in polyester production.

The strength of titanium is 3.5 times that of stainless steel and 1.3 times that of aluminum alloy, and TiO₂ is a brittle compound. With long-term cutting friction, the rotary knife and fixed knife The blade will be severely worn.

Therefore, under the premise of ensuring the inherent quality of PET products, the amount of TiO₂ added can be appropriately reduced, which not only reduces the cost of raw materials but also extends the service life of the cutting knife.

Influence of cooling water

The temperature and flow of cooling water have an important impact on the appearance quality of the slice and the service life of the cutting knife.

If the temperature is too high or the flow is insufficient, the ester strip cannot be cut normally due to insufficient cooling, resulting in continuous cutting or lump material; the temperature is too low or Flow the brick is too large, the ester strip will be caused by excessive cooling.

It is brittle, which increases the difficulty of cutting and shortens the service life of the cutting knife.

At the same time, the cutting process towel will produce a lot of powder, and the powder will block the filter and spray nozzle in the cooling water and cause insufficient flow.

Quote-[1] Liu Zhonghui, Zhang Guoyue. Cause analysis and countermeasures affecting the service life of the cutting knife of the underwater pelletizer [J]. Chemical Machinery, 2012,039(006):811-813,822