Characteristics and improvement of template technology

Process characteristics of cermet sheet composite template

The granulation belt of the template is formed by the template body (1Cr13 stainless steel and cermet sheet vacuum brazing process welding) early using the die hole inlaid alloy cylinder to open holes because the surface and the inside of the material are different, the expansion coefficient is different.

The body is easy to collapse, resulting in poor cutting effect) Welding metal-ceramic sheets effectively solves this problem.

Moreover, the material belt adopts TiC-NiCr cermet hard wear-resistant material, which has a better heat resistance and corrosion resistance than traditional WC-Co hard alloy and TiC-Fe steel bonded gold, but at the same time, due to its cermet surface and body Open welding of the welding surface directly affects the service life of the template.

Therefore, perfecting the welding process and improving the welding quality is a prerequisite for ensuring the use.

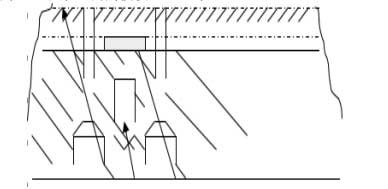

(Vacuum layer of ceramic alloy layer for heat conduction medium channel)

Crafts improvement

The template granulation belt works underwater at 60~70℃, and the inside of the template needs to be heated to about 260 in order to maintain the molten state of the material.

In order to avoid more heat loss, the vacuum insulation layer technology is adopted.

The principle: heating channels in the body When the upper groove is vacuum welded to the pelletizing belt sector block, a vacuum layer is naturally formed, and the actual temperature of the template of the polypropylene pelletizing line can be increased by 9-12°C without changing the heat transfer pump capacity.

Effectively improve the heating efficiency and increase the opening rate of the template.

Quote- [1] Qin Yujun. Application of metal composite ceramic template cutter in plastic pelletizing [J]. Industry, 2016,000 (007): P. 267-268