Application of metal composite ceramic template cutter in plastic pelletizing

In the polymer pelletizing process, the quality of the pelletizing knife and template directly affects the appearance of the product, affecting the long-period operation of the pelletizing unit, and the loss of the cutter is large, which increases maintenance costs.

Characteristics of TiC-NiCr metal composite ceramic materials

Cermet is made by using a certain metal or alloy as the bonding phase, using refractory metal compounds (mainly titanium carbide or tungsten carbide) as the hard phase, and sintering by powder metallurgy (similar to ceramic art).

Its structure is characterized by the fine hard phase crystal grains evenly and dispersedly distributed in the metal or alloy body.

The main chemical components of the newly developed cermet materials are TiC-TiC-NiCr, in which the binder phase is Ni, Cr and a small amount of Ti, Al.

Ni can form a solid solution with Cr, and its red hardness can reach 800°C. Ensure that the hard phase is not easy to fall off during work, improve the wear resistance of the blade, and have better performance than the Fe-based steel cemented carbide materials used in the cutter and template body materials in Germany and Japan.

The Fe substrate is easy to oxidize. Easy to anneal, easy to wear

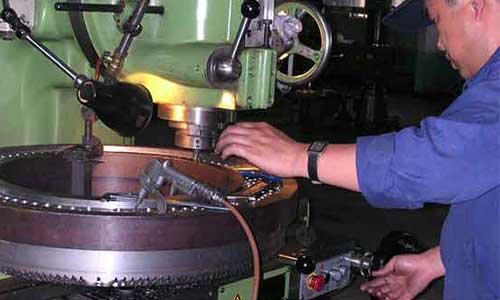

Process characteristics of TiC-NiCr metal composite ceramic cutter

The blade adopts TiC-NiCr. The body material adopts 40Cr and 3Cr13, which has sufficient strength and toughness; the body and the blade have good welding performance, and the blade and the blade adopt vacuum reactive diffusion welding technology.

The principle is that as the temperature rises, the oscillation amplitude of the molecules increases, and the gravitational force between the molecules decreases.

The combination of the knife body and the knife-edge forms a solid solution of NiCr alloy and Fe eutectic composition at high temperature.

This solid solution forms a strong transition zone between the two materials.

The comprehensive performance (resistance to external force denaturation) of the composite pelletizer is significantly improved than that of single steel or TiC-NiCr, and its bending strength can reach 2500MPa. Integrated cermet fragile knife.

Quote-[1] Qin Yujun. Application of metal composite ceramic template cutter in plastic pelletizing [J]. Industry, 2016,000 (007): P. 267-268