Common problems and countermeasures of plastic granulation-Solution

In the production of different melt indexes, the cutters that are suitable for different melt indexes of material formulas are matched with the template, and their hardness and bending strength are different.

At the same time, different batches of knives may have quality defects, which can be gradually overcome with the continuous improvement of the technical quality control system.

If the pelleting effect is not good during the pelletizing process, the debris increases, and some plastics are more likely to be in the form of film Paste on the blade edge and the template discharge port to accelerate the wear of the template and the cutter.

At this time, do not forcefully increase the knife pressure. This will only make the front section of the blade upwards, the root will increase wear, and the cutting particles will worsen and cause the broken knife to be wrapped around the knife.

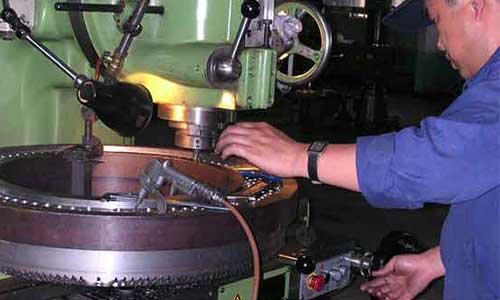

If you encounter this situation, you need to re-grind the knife-there is no material knife and the template relative to each other, so that the cutting blade and the template granulation belt contact more than 90%, and the blade is sharp and smooth without notches, and then drive to cut pellets, can achieve good results.

The friction coefficient of the domestic cermet is 0.145, which is less than 0.280 of the German WP pelletizing knife. Therefore, some cutters have less wear on the template and require a long time to sharpen the knife during the initial use.

If the template is run for a long time, the template will have a circular groove. If the hardness of the template is greater than the relative mutual grinding of the cutters and the effect cannot be achieved, it must be sent to a professional manufacturer for grinding treatment.

Quote-[1] Qin Yujun. Application of metal composite ceramic template cutter in plastic pelletizing [J]. Industry, 2016,000 (007): P. 267-268