Development and application of Cermet Pelletizer knife

The plastic pelletizing knife is one of the key easy-to-wear parts in the production process of polyethylene and polypropylene plastics.

The quality of its quality directly affects the quality and output of plastic particles. It has long been dependent on imports, and its performance and life are long.

The length directly affects the quality and output of the product.

After the plastic resin is extruded by the screw, it passes through more than 1,000 small holes with a diameter of 2.6mm in the template.

At the same time, the 16 pelletizing knives in the underwater pelletizing system are close to the surface of the template under the action of 20kgf/cm² force.

Revolving to cut pellets, so the pellet cutter needs to use materials with good wear resistance, impact toughness, and corrosion resistance.

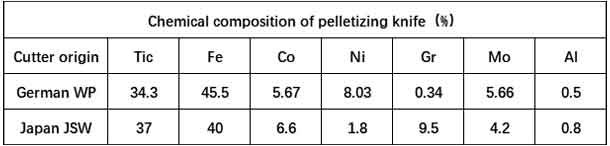

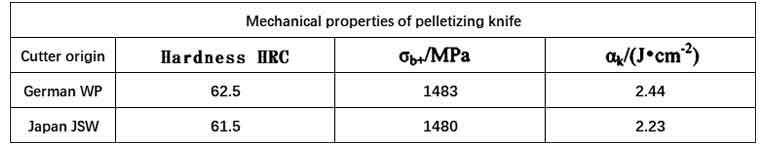

The material and performance of the pelletizing knife used in the extruder of German “WP Company and the extruder of Japanese JSW Company are shown in Table 1 and Table 2.

Table 1(Chemical composition of pelletizing knife)

Table 2(Mechanical properties of pelletizing knife)

From the above analysis results, it can be seen that the imported pelletizing knife is made of steel-bonded cemented carbide, which has good impact toughness.

Due to the large number of Tic hard particles distributed in the structure, this material has high wear resistance.

The main form of failure of the pelletizer is worn. The pelletizer and the template embedded with the cemented carbide block move very quickly.

Due to the frictional heat and the working temperature (the template is at 280℃), the cutting edge of the tool is working.

The temperature rises quickly, and these harsh working conditions make the pelletizing knife wear. Secondly, the pelletizing knife is also subjected to certain vibrations and shocks when working, and sometimes the pelletizing knife fails due to chipping.

According to the operating conditions of the pelletizing knife and the analysis results of the imported pelletizing knife, the national

The development idea of the pelletizing knife:

(1) High-performance cermet is selected for the cutting edge to improve the wear resistance of the knife;

(2) Alloy steel is used as the knife body to improve the strength and impact resistance of the knife;

(3) ) Vacuum diffusion welding is used to firmly combine the blade and the blade body.

Quote-[1] Development and application of cermet cutter [C]//2016 National Polyethylene Production Technology Exchange Conference.2016