Operation and optimization measures of underwater granulation system (2)

Optimization of severe tool root wear

Main phenomenon: The blade root of the pelletizing knife is severely worn, and there are a large number of tailed particles and scraps in the produced material particles and the phenomenon of entanglement of the knife, which will also cause serious wear of the inner ring of the template pelletizing belt.

The cause is:

the knife pressure is too high or the locking mechanism is invalid;

the cutter head speed is too low, causing the pressure of the cooling water to the pelletizing knife to be lower than the pressure of the cutter head;

the equipment is running under low load and the pelletizing output is too low, forcing the cutting the speeds of the cutter head of the pellet cutter is reduced.

Under normal circumstances, the simplest way to adjust the severe wear of the blade is to properly adjust the blade pressure, appropriately adjust the speed of the cutter head, and adjust the granulation load to reduce the wear of the cutter head.

Optimization of severe tool root wear

If the granulator, cutter head, and granulating template want to complete the granulating process well, they must coordinate with each other.

The pressure of the main shaft of the cutter head on the template direction, the rotating speed of the cutter head, the length of the granulator, the temperature and flow rate of the cooling water, the melt index of the plastic, the output and so on all need to be adjusted according to the specific situation.

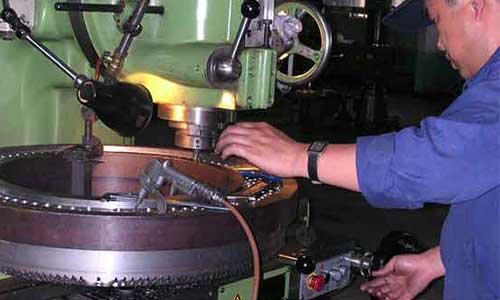

We can take advantage of the opportunity of the temporary parking of the equipment to observe the wear state of the template or granulator according to the wear condition of the blade of the cutter, adjust the rotating speed or pressure of the cutter head appropriately.

If the rotating speed or pressure exceeds the adjustment limit of the equipment due to the output, the number of knives on the cutter head should be reduced or increased.

Quote-[1] Yang Zhongbo. Causes and optimization of the failure of the underwater pelletizer for polypropylene technology [J]. Petrochemical Technology, 2017, 024(010): 26-27