Operation and optimization measures of underwater pelletizing system

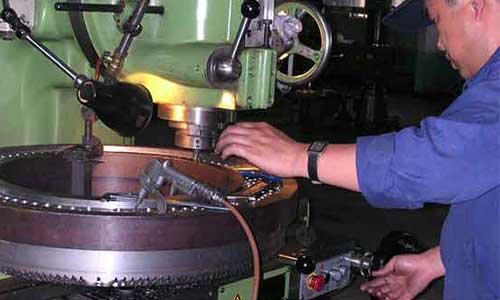

Optimization of granulation Template

The early steam heating granulation template uses high-pressure steam to enter the outer ring and inner ring of the granulation belt to heat the working area of the granulation template.

The disadvantage is that the temperature difference of the granulation belt is large and the material particles are not uniform.

At present, the granulation template uses heat transfer oil as the heating medium and some kind of inlet and outlet heating channel as a unit and arranges dense heat conduction channels along single row or double row discharge holes under the granulation belt of the template, the temperature difference of the granulation belt is small, and the granulation quality is greatly improved.

With the continuous improvement of the production capacity of the single-machine granulating unit, the heat transfer oil heating method which is convenient for temperature control is gradually adopted.

Optimization of severe tool tip wear

This kind of phenomenon occurs when the materials and the granulation water are not well-matched with the feeding knife when granulation is started.

Main phenomena: the blade tip of the granulator is seriously worn, and there are a large number of particles with the tailor channeling material in the produced material particles, which causes serious wear of the outer ring of the template granulation belt.

The causes are: the parallelism between the fixed cutter head and the template granulation belt is too poor;

The granulator is not in place, the cutter pressure is too low or out of pressure and the rotating speed of the cutter head is too high, the pressure of cooling water on the granulator is higher than that of the cutter head;

When the equipment is overloaded, the granulation output exceeds the designed capacity of the equipment, and the speed of the cutter head is forcibly increased.

Therefore, proper adjustment of the parallelism between the cutter head and the template granulation belt, adjustment of the cutter pressure, and proper reduction of the load can ensure that the tooltip reduces wear.

Quote-[1] Yang Zhongbo. Causes and optimization of the failure of the underwater pelletizer for polypropylene technology [J]. Petrochemical Technology, 2017, 024(010): 26-27