Plain bearing

Product description

Sliding bearings are the key components of gear pumps in mixers, also known as bearing bushes. This part is the key factor restricting the cycle operation of the production line.

Structure

The sliding bearing is a two-body combination structure, which is composed of a bearing outer sleeve and a bearing inner sleeve. After hot-installing the two, add anti-rotation pins at the connection to make the two interlock.

The bearing sleeve is made of a high-quality alloy structure. After forging, tempering, quenching, and stabilization treatment, it has high comprehensive mechanical properties.

The material of the bearing inner sleeve is composed of high-quality carbon steel and a silver layer with a thickness of 1 mm. The purity of the silver layer is 99.9%, and the ion spray process is used.

Success case

The sliding bearing produced by Shenyang Jinfeng for Beijing Yanshan Petrochemical was put into use in June 2016. It was successfully driven once, running smoothly, and the effect was good.

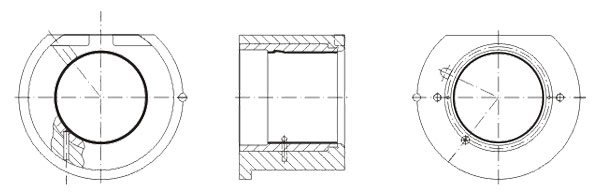

Right bearing bush-Sketch

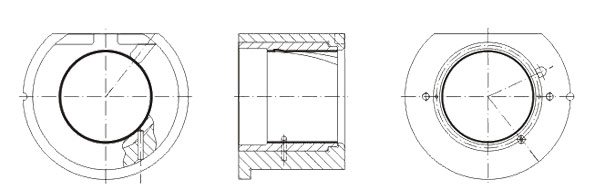

Left bearing bush-Sketch

Key process

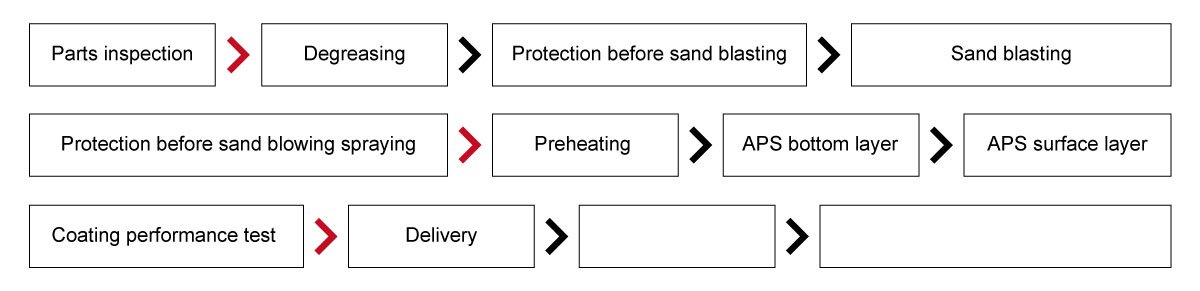

Silver coating spraying is the key process. The silver coating is quickly heated to a molten or semi-molten state by a plasma spraying device, and is quickly deposited on the inner surface of the steel jacket by means of air atomization, thereby forming a coating that is tightly combined with the steel substrate. The process of coating production is as follows:

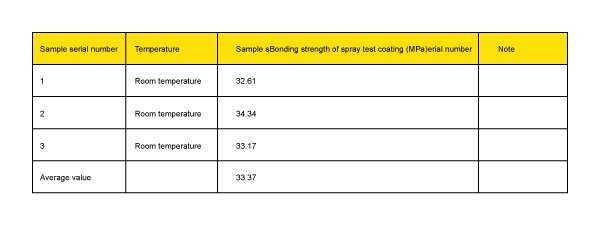

The bond strength of the silver coating obtained through this manufacturing process is tested by a tensile tester according to the “Hot Coating Coating Structure Strength Test Method” (HB5476-91). The inspection results are as follows:

Coating bond strength results

Microhardness of coating