Reformation design of underwater pelletizer cutterhead of HDPE plant-Technical transformation plan

Application of rubber flexible cutter head

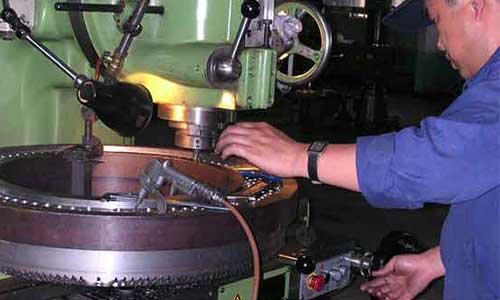

In view of the existing problems of the cutter head, after careful research and demonstration, the original fixed cutter head of the equipment was changed to a rubber flexible cutter head, as shown in Figure 2.

Compared with the fixed cutter head, the flexible cutter head has the function of fitting compensation. Depending on the miniature deformation of the rubber layer, there can be a compensation deflection angle of 2~3 degrees on the axis, it can compensate the parallelism between the cutter head and the template.

Image 2 (Cutter head structure after transformation)

Transmission mode transformation

Change the original triangular shaft drive mode of the cutter head to single-key transmission.

Use a counter-threaded bolt in the center of the cutter head to fix the cutter head on the cutter shaft. As the cutter head rotates, the pre-tightening force of the bolt will be greater.

Lead to loose bolts and changes in cutter clearance.

The single-key transmission can not only effectively meet the transmission technical requirements of its original equipment, but also has the characteristics of simple processing and manufacturing, convenient installation and maintenance. The most important thing is that this simple structure avoids the cutter and template caused by the wear of the cutter shaft. The gap changes, the reliability is stronger.

Quote-[1] Wang Wei, Guo Wenpeng, Zuo Lijian, Sun Xiumin. Modification design of cutter head of underwater pelletizer for HDPE device [J]. Refining and Chemical Industry, 2016, 027(002): 46-47

Increase hydraulic holes

In this transformation, the diameter of each cutting knife on the cutter head is increased to Φ15 mm hydraulic hole.

The hydraulic hole has a certain angle with the end face of the cutter head, and the direction is the same as the rotation direction of the cutter head.

When the cutter head rotates, it can produce a pumping effect on the granular water, so that each cutting knife position forms a pressure water column, which can more directly wash the granulation surface, so that the polyethylene particles can quickly leave the cutting area, which can effectively prevent the polyethylene Particle adhesion can reduce the occurrence of pad knife, wrap knife, cavitation, etc,and better ensure the pelleting effect.

At the same time, the complex cutter shaft water system is reduced, and the reliability is greatly improved.