Reformation design of underwater pelletizer cutterhead of HDPE plant

The device has a problem

Difficult to operate the cutter head

The cutter head of the original pelletizing machine is a fixed cutter head, and the gap cutting method is adopted between the cutter head and the template.

The operating regulations require that the gap between the cutter and the template be controlled between 0 and 0.01 mm, which is an important factor for the installation level of the operator.

A big challenge. If the gap is too small, it will cause excessive wear of the cutter and template, increase production costs, and even cause equipment accidents.

If the gap is too large, it will cause the phenomenon of pad knives and wrap knives, resulting in unqualified product quality.

In actual operation, the cutter head gap is also affected by the temperature of the particle water, and the cutter shaft will elongate or shorten with the change of the particle water temperature, resulting in the change of the gap between the cutter and the template, which further increases the difficulty of adjusting the gap between the cutter shaft and the template.

Insufficient tool axis positioning

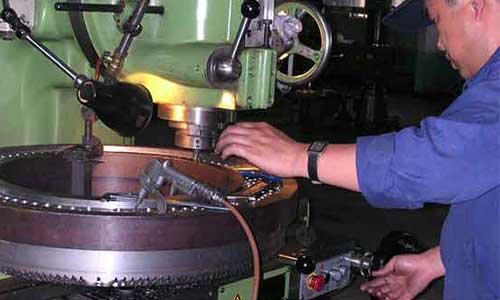

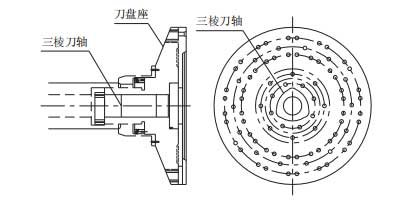

The original pelletizer uses a triangular shaft and a self-locking device to position the knife shaft, as shown in Figure 1.

Image 1(Reform the front cutter head structure)

The triangular shaft ensures the transmission in the circumferential direction of the cutter shaft and the parallelism between the cutter head and the template, and the self-locking device at the end of the cutter shaft ensures the axial positioning of the cutter shaft, that is, to achieve the same effect of the gap between each cutter and the template.

Because the triangular shaft matches the shaft sleeve in clearance, the cutter shaft has micro-motion effect in the shaft sleeve, and the micro-motion effect will increase sharply after wear, which leads to the acceleration of wear rate and vicious circle.

Therefore, the parallelism between the cutter head and the template cannot be guaranteed after the abrasion of the cutter head occurs after long-term use, which causes the gap error between the cutter and the template and causes adverse effects on normal production.

At the same time, the same problem exists between the self-locking device and the pelletizer shell, which directly leads to the change of the gap between the cutter head and the template.

The particle separation effect is not ideal

The original pelletizer uses a knife shaft water system to promote the separation of particles and cutters, that is, a hollow shaft is used to inject a certain pressure of pellet water in the center of the cutter head.

The effect of this method is poor, and the granular water needs to pass through the bearing box and gap adjustment device of the entire pelletizer, involving multiple complicated parts such as mechanical seals.

After the mechanical seal fails, the granular water will pollute the lubrication system and cause equipment lubrication accidents, Poor reliability.

Quote-[1] Wang Wei, Guo Wenpeng, Zuo Lijian, Sun Xiumin. Modification design of cutter head of underwater pelletizer for HDPE device [J]. Refining and Chemical Industry, 2016, 027(002): 46-47