Research on granulation technology of underwater granulator ——Location prone to failure

1. Introduction to the principle of underwater granulation

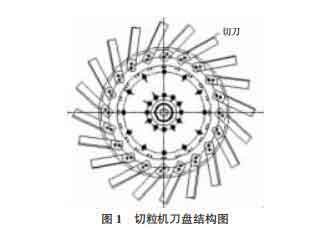

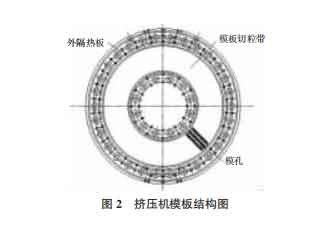

As shown in Figure 1 and Figure 2, the polyethylene material during production is in a molten state.

After being pressurized and homogenized by the screw of the extruder, it enters the template.

The material is evenly extruded along the template hole under pressure, and there are 20 The circular cutter head of the cutter is attached to the template under pressure and rotated at high speed.

The cylindrical polyethylene material extruded from the template hole is cut into granules.

The template and the cutter are sealed in water. The flow cools and solidifies the polyethylene particles and transports them to the centrifugal dryer section for water removal and drying.

Image 1(The structure diagram of the knife holder of the granulator)

Image 2(Extruder template structure diagram)

2.Failure analysis

(1) Wrap the knife.

The material melt index is too high, and the corresponding extruder barrel temperature and pellet water temperature are not adjusted in time. Or the cutter blade is not attached to the template.

(2) Pad knife.

Before starting the pelletizer, the surface of the template was not cleaned up, there was material between the cutter and the template, and the template and the cutter were not coated with sufficient lubricating oil,making the material stick to the cutter and preventing the material from rotating with the cutter Discharge, causing the gap between the cutter and the template to be too large, the extruded material in the die hole is severely deformed, and the regular particles cannot be cut to form a cushion material.

(3) The mold hole is blocked.

If the downtime is too long, the template will be cooled by air, and part of the polyethylene material in the mold hole will cool and harden, thereby adhering to the inner wall of the mold hole, resulting in uneven discharge of the mold hole.

(4) Trailing particles.

The main reason is that the cutting edge is not sharp and the material cannot be cut effectively and quickly; this phenomenon can also occur if the cutter head feed pressure is too high, and the outer edge of the cutter is raised or the feed pressure is too small, so that the inside of the cutter does not fit on the template.

(5) Lots of debris.

The surface of the template is not smooth for a long time, which causes deep groove marks on the surface of the template.

Quote-[1] Yang Xue, Fan Tiesheng. Research on granulation technology of LDPE device extruder/underwater pelletizer [J]. Mechanical Engineer, 2015,000 (005): 235-236