Research on template of underwater pelletizer

Overview of underwater pelletizer

The working principle of the traditional waste plastic recycling extrusion granulator is to melt and filter the plastic through a single-stage or two-stage extruder, extrude into strands, then cool and solidify and then pelletize.

The underwater pelletizer is a new type of machine that can directly cut pellets by contacting cooling water when the surface of the melt extrusion die does not need to be stretched or cannot be stretched.

Melt granulation has more obvious advantages than solid granulation.

1.1 Main equipment composition of underwater pelletizer

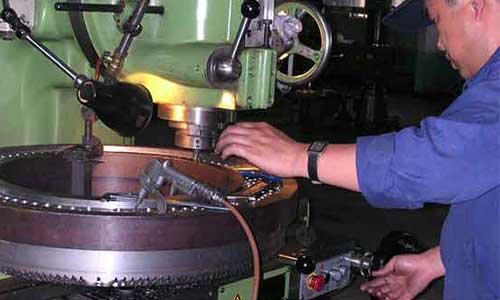

The main equipment of the underwater pelletizing unit includes: die head, water chamber and cutter head assembly.

The die head is composed of a template and a template seat. The template seat is connected to the downstream side of the screen changer through a flanged middle tube, and the template is connected to the other end of the template seat.

The center part of the template seat is jacketed and has a conical shape, which will make the polymer flow in a laminar tube-like flow.

The template is a hot channel with drilling holes. There are multiple heating medium inlet and outlet nozzles on the template. In order to heat effectively, the heat medium supplied to the template is distributed to each internal heat channel of the template.

1.2 Heating method of template

At present, there are basically three heating methods for the pelletizing template:

(1) Electric heating: generally applicable to small granulation equipment with an annual production capacity of less than 10,000 tons.

(2) Steam heating: generally applicable to pelletizing equipment with an annual output capacity of less than 70,000 tons.

(3) Oil heating: currently used in granulating equipment with a large annual production capacity.

Generally, a small granulation template is installed with a number of heating rods through the heating holes on the outer circular end surface to heat the granulation area of the template.

Its characteristics are rapid heating, flexible and stable temperature control.

The early steam-heated pelletizing template used high-pressure steam to enter the outer ring and inner ring of the pelletizing belt to heat the working area of the pelletizing template.

The disadvantage is that the temperature difference in the granulation zone is large and the material particles are not uniform.

The granulation template uses steam or heat transfer oil as the heating medium, and uses a certain type of heating channel as the unit.

Under the template granulation belt, dense heat conduction channels are arranged along the single row or double discharge holes, and the temperature difference of the granulation belt is small.

Granulation quality substantial improvement, with the continuous improvement of the production capacity of the single-machine granulation unit, the heat transfer oil heating method that is convenient for temperature control is gradually adopted internationally.

Quote-[1] Liu Wei. Research and domestic application of underwater pelletizer template [J]. Petroleum and Chemical Equipment, 2015,000(010): 8-12