The main structure of the underwater pelletizer

Rotary knife

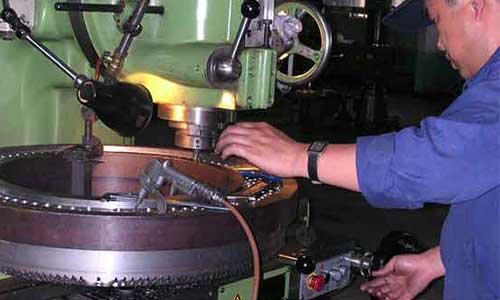

The base of the rotary knife is made of corrosion-resistant stainless steel SUS304, and the blade is made of Stellite cobalt-based alloy composite knife (STEL-LITE 12#), which is formed by high-tech numerical control ion welding.

The standard outer diameter of the rotary knife is 162.5mm, and the repair limit diameter is 154mm.

At this time, an aluminum spacer should be added to the corresponding fixed knife.

It is composed of 30 pieces of 2° helical teeth, the effective working length is 680mm, and the supporting bearing model is 6214 2RSR.

The cross section and parameters of the rotary knife edge are shown in Figure 3.

Image 3(Cross section of rotating blade)

Fixed knife

Fixed knives usually use two materials, tungsten carbide, and ceramics with high hardness and strong wear resistance.

Each pelletizer is equipped with two fixed knives, and each fixed knife has 4 90s. Sharp cutting surface.

The standard rectangular cross-section size is 20mm x 8mm, the grinding limit is 19.6ram×7.6mm, and the working length is 350mm.

Since the fixed knife will wear 30 times per revolution, the wearing frequency is very high, so if a cut occurs if the point is recessed and the cutting edge loses sharpness, the blade face needs to be replaced.

skin-peeler

The skinning knife is also called “scraper”, and its material is stainless steel SUS304.

Installed between the fixed knife holder and the bottom roller for scraping the role of silk.

Guide rollers

The lead roller of the pelletizer is composed of upper and lower rollers.

The outer diameter of the top roller is 170mm, the surface has 24 2° spiral teeth, the working length is 680mm, and the surface is sandblasted.

Two cylinders with a working pressure of 0.2-0.3MPa generate a pressing force on it to support the bearing model It is 20208T.

The outer diameter of the bottom roller is 90mm, the material is 1Cr17Ni2, the working length is 680mm, the surface is smooth, and the support bearing model is 6308 NSEC3.

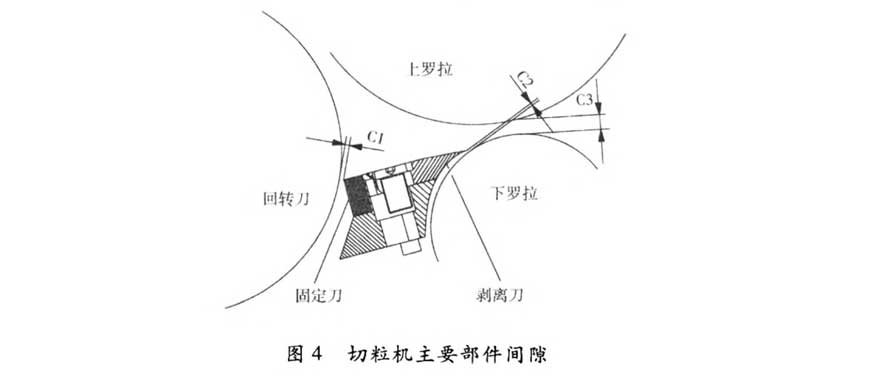

Gaps between main components

The gap between the main components of the underwater pelletizer is shown in Figure 4.

Image 4(Cross section of rotating blade)

In Figure 4, C1 is the cutting gap, which refers to the gap between the rotary knife and the fixed knife, which directly affects the appearance quality of the slice and the service life of the cutting knife;

C2 is the peeling gap, which is the gap between the peeling knife and the bottom roller. which directly affects the operating cycle of the pelletizer and the service life of the bottom roller;

C3 is the lead gap, which is the gap between the top roller and the bottom roller, which directly affects the appearance quality of the slice and the operating cycle of the pelletizer.

Quote-[1] Liu Zhonghui, Zhang Guoyue. Cause analysis and countermeasures affecting the service life of the cutting knife of the underwater pelletizer [J]. Chemical Machinery, 2012,039(006):811-813,822