The solution to the short running cycle of the cutter of JSW granulator

Analysis of the reasons for the short running cycle of the cutter

Equipment reason

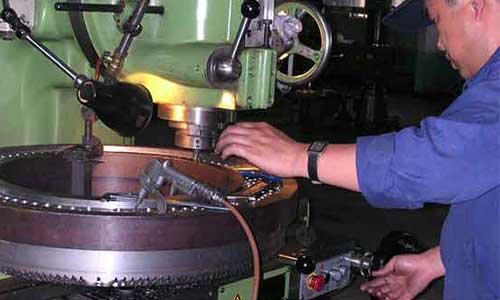

For seamless cutting, the friction between the cutter and the template during the pelletizing process is the main factor affecting the service life of the cutter.

In the case of a certain friction coefficient, the appropriateness of the pressure of the cutter acting on the template (the value of the cutter must not only make the cutter reach its designed operating cycle, but also have appropriate wear every day to maintain the sharpness of the cutter)

It is the essential factor that affects the operating cycle of the cutter. The cutter force of the JSW underwater pelletizing unit is shown in Figure 1.

Image 1 (Underwater pelletizing unit cutting force diagram)

Process operation reason

During the start-up process, the initial set pressure during manual feed does not match the cutter speed, which causes the feed pressure to be too high, causing 3 to 5 cutting edges to wear under the condition of no material.

In addition, at the beginning of the start-up, the blanking volume was low and the resin extrusion speed was low, which is another reason for the short service life of the cutter.

The Measures Taken

Regarding the setting of the cutter pressure curve, if the pressure setting is too low, not only the normal operation of the pelletizing unit cannot be maintained, the cut pellets do not meet the product quality requirements, but also the major “enema” of the pelletizing system is very likely to occur in the production. accident.

The setting data is shown in Table 2, and the cutter feed curve is shown in Figure 3.

Table 2 (Data of cutter after resetting)

Image 3 (Data of cutter after resetting)

Compared with Figure 2, the three-point linear relationship of the pressure curve equation in Figure 3 is better than that in Figure 2. In actual production, the speed of the cutter is generally controlled at 350~500r/min, so the data range taken is close to the actual production.

Under the action of the feed pressure set at a certain speed, the continuity and uniformity of the forward speed of the cutter axis are better.

When the cutter moves continuously from the starting point, the speed is about 2 to 3 passes/s, and The speed is relatively stable, and the data obtained is more reasonable.

In the actual setting process, optimize the operation of manually changing the cutter feed pressure:

1) At the beginning of the start-up, the manual setting value of the cutter is calculated according to the adjusted formula, and the feed pressure control loop is automatically turned on as soon as possible;

2) It is stipulated that the blanking volume at the initial start-up period should not be less than 5t/h;

3) Optimize the start-up procedure to reduce the no-feed operation time of the pelletizing unit.

Quote-[1] Zhang Yong. Solution to the short running cycle of the cutter of JSW pelletizer [J]. Guangzhou Petrochemical Technology, 2005,000(004): 12-14