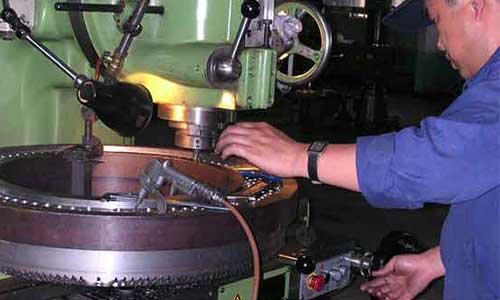

Wear analysis of pelletizing knife in extrusion pelletizing unit 2

In addition to the friction between the cutting edge and the template cutting belt, the main reason for the wear of the pelletizing knife is the wear and cavitation caused by the repeated sticking and shedding of the chip collecting edge and the injury of the cutting edge.

The friction between the knife edge and the template cutting belt usually occurs during the running-in period of the new knife and the template.

This will only make the cutting blade contact more ideally with the template cutting belt, and will not cause damage to the cutter and the cutting belt. Another type of wear is abnormal wear. After replacing a new knife, do not sharpen the knife carefully.

At least 85% of the edge band is not ground and drive to pelletize. When the work is not long, the tailings begin to increase.

The cutting edge of the tool has been set up at a position where the inner and outer circles of the pelletizing belt are not involved in the work, and the knife is forced to advance. The gap between the tip of the blade and the template granulation belt increases and the tailings increase instead.

At this time, the wear of the tool and the template are intensified, and in severe cases, the result of the tool being wrapped and unable to drive. It can be seen that the tool is not running well.

The blade wear is more obvious. Therefore, after replacing the new knife, be sure to drive the knife after the knife and the template are fully run in.

Due to the long-term operation of the equipment, when the template is heated and cooled alternately, the die mouth expands and deforms, and the edge of the die mouth is not sharp or damaged.

In addition, the pelletizing knife is limited by the working conditions of the water chamber, and the force is relatively complicated, including the force of the pelletizer set by the southern operator, the hydrodynamic effect of the pelletizing water on the blade when the blade is rotating in the water, and the generation of the blade on the surface of the template.

The reaction force and so on. As a result, the shear rate and shear stress at the mold U is increased, which makes the cutting of the material unsatisfactory. The material chips produced by cutting are concentrated on the die mouth in a nodular shape and repeatedly stick and fall off.

The cutting water is at the cutting edge during cutting. Cavitation occurs, which intensifies the wear of the surface of the template cutting belt and the cutting knife.

Quote-[1] Wang Shijun. Wear analysis of pelletizing knife in the extrusion pelletizing unit[J]. Equipment management and maintenance, 2010,000 (002): 65