Wear analysis of pelletizing knife in extrusion pelletizing unit

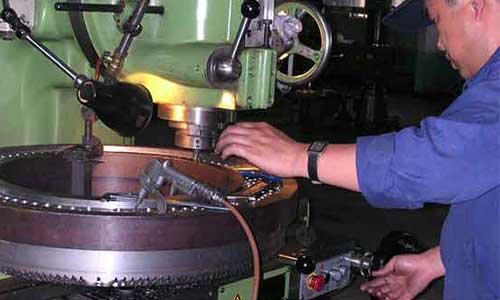

The main equipment for material granulation is a granulator, which adopts an underwater granulation method.

The fixed part of the host is composed of a centrally heated template. The template has a sufficient number of die holes to ensure output.

There is a heating channel in the corresponding position. Steam or hot oil is used for heating and heat preservation to avoid clogging the die holes during startup and operation.

The polymer flows into multiple streams through the die holes and enters the pelletizing chamber. The cutting of particles consists of a water chamber and a set of cutters that rotate relative to the template.

Cut the current into small pieces. The particles stay in the cutting water for a sufficient time to cool them to a temperature suitable for transportation.

The granulation water in the water chamber is used to cool, solidify and transport the granules. Due to the relative movement of the template and the pelletizing knife in the pelletizing unit.

The template cutting belt and the cutting knife inevitably contact and wear. The working principle of the underwater pelletizing unit is basically the same, that is, the cutting tool and the template move relative to each other without gaps and positive pressure.

Or in relative motion cutting, the gap is 0.02~0.05mm. In actual operation, since the material of the template cutting belt and the cutting blade is basically cermet or other hard metals, the friction coefficient is very small, and the wear between the tool and the template cutting belt is small.

In addition, since the pressure generated by the fin melt acts on the pelletizing knife during the extrusion process, the possibility of direct contact between the template pelletizing belt and the pelletizing knife is very small.

Quote-[1] Wang Shijun. Wear analysis of pelletizing knife in extrusion pelletizing unit[J]. Equipment management and maintenance, 2010,000 (002): 65