Working principle and conditions of pelletizer template

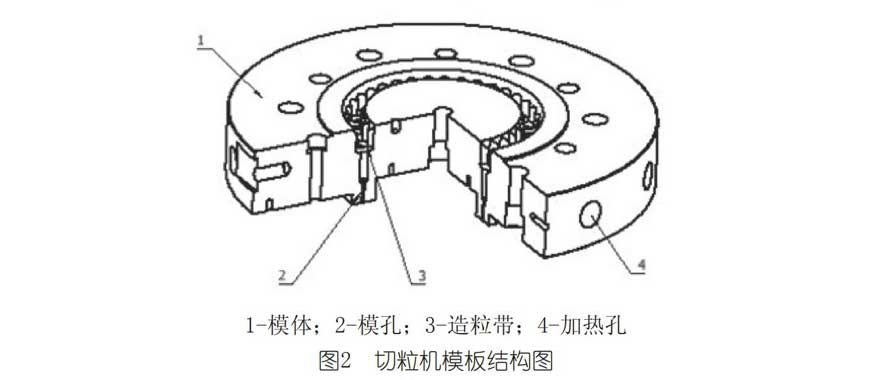

The template structure of the pelletizer consists of four parts: the mold body, the polymer molding hole (die hole), the heating hole, and the pelletizing belt (hard alloy composite layer), as shown in Figure 2.

Image 2 (Pelletizer template structure diagram)

Die body: The main body of the template, which is used to connect the extruder, the water chamber of the pelletizer, the polymer flow channel, the heating rod, and the pelletizing belt. The cemented carbide is embedded on it to play the role of the skeleton.

Die hole: The molten polymer is extruded from this channel.

Heating hole: used to install a heating rod to heat the molten polymer.

Granulation belt: the core part of the template. After the high-temperature molten polymer is extruded, the high-speed rotating cutter cuts pellets here. The material requirements are relatively high, not only must have high hardness, but also have wear resistance, high temperature resistance, and corrosion resistance.

How templates work

The molten polyethylene plastic is pressurized to 5.0 MPa through a twin-screw extruder, filtered through a screen changer to remove possible impurities, and then split into multiple runners of the template, where the material is accelerated due to the decreasing diameter of the runner

The discharging end finally enters the pelletizing water chamber in a linear form through the die hole, where the molten polyethylene is instantly cooled by the pellet water at 50-70°C, and is cut into 2 by the high-speed rotary cutter that is closely attached to the surface of the template.

-4mm long, 2.5-3.5mm in diameter polyethylene particles, the entire granulation process is completed, and the particles are finally transported by cooling water to the centrifugal dryer for dehydration and drying.

Template working conditions

Polymer extrusion pressure: about 4.0~5.0 MPa; working temperature: 220~240℃; water temperature in the pelletizing room: 50~70℃.

The template is an important part of the underwater pelletizing system, with three functions such as forming, heating, and cutting.

The template has many molding holes and nozzles with a special structure, which can mold the molten viscous plastic and minimize

The function of pressure loss. To prevent the polymer from solidifying in the cavity, various forms of heating holes are designed in the template.

These heating holes are used to place heating rods to heat the molten polymer.

Quote-[1] Wang Jian, Liu Wei, Zhang Peng, Zhang Xiaokui. Analysis of the pressure field of the template fracture of the underwater pelletizer[J]. Petroleum and Chemical Equipment, 2012, 000(009): 21-24