Working Principle Of Underwater Pelletizer

The high-temperature and high-viscosity polymer melt is extruded through 64 holes regularly arranged by the casting head (18CU01) and then introduced into the pelletizer (19CU01) in the shape of a strip (ester strip) through a cluster guide with a cooling length of 3,000 mm.

Among them, the installation position of the cluster guide plate device is lower than the position of the casting head, and the ester strip is cooled and transported in three forms (overflow water, spray water, and conveying water) by using demineralized water.

The PET chips are transported to a centrifugal dryer (19D01) and then separated by a vibrating screen (slice classifier) (19G01) to obtain products with qualified appearance.

Except for a small part of the vaporous demineralized water is discharged to the outdoors, the rest of the liquid demineralized water is recycled to the storage tank (193E01), and a large amount of PET powder and other impurities are filtered out by the centrifugal pump (191E01).

Under the action of the plate heat exchanger (19E01), the demineralized water with a suitable temperature is obtained, and it is re-transmitted to the pelletizing system for recycling. The pelletizing system process is shown in Figure 1.

Image 1(Process flow of granulation system)

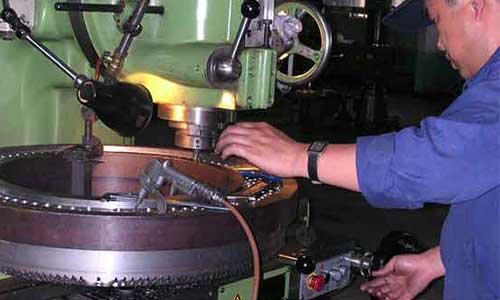

The ester strip enters between the rotating knife and the fixed knife under the action of the upper and lowers roller guide rollers, and the ester strip is cut by the rotation of the rotating knife.

Since the center of the cut pellets has not been completely cooled and is in a semi-molten state, it is further cooled by conveying water and the slices are conveyed to the dryer.

The working principle of the underwater granulator is shown in Figure 2.

Image 2 (Process flow of granulation system)

Quote-[1] Liu Zhonghui, Zhang Guoyue. Cause analysis and countermeasures affecting the service life of the cutting knife of the underwater pelletizer [J]. Chemical Machinery, 2012,039(006):811-813,822